In the rapidly evolving landscape of industrial applications, the choice of valve technology plays a crucial role in optimizing performance and efficiency. Among the various options available, wafer valves have emerged as a preferred choice due to their compact design, lightweight structure, and ease of installation. According to a report by MarketsandMarkets, the global industrial valves market is projected to reach USD 90 billion by 2025, with wafer valves contributing significantly to this growth due to their versatility and cost-effectiveness.

The designs of wafer valves allow for efficient flow control and a reduction in pressure loss, making them ideal for applications in sectors such as oil and gas, water treatment, and chemical processing. As industries increasingly focus on enhancing operational efficiency while minimizing costs, the adoption of wafer valves is set to rise. Furthermore, their compatibility with various piping systems and ability to withstand high temperatures and pressures underscore their utility in a broad array of industrial scenarios. This article delves into the top 10 benefits of wafer valves, highlighting how they can enhance performance and efficiency in diverse industrial applications.

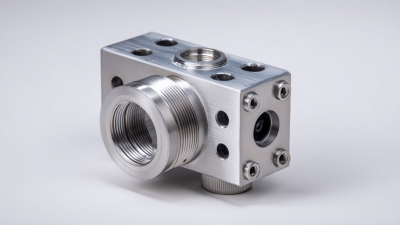

Wafer valves have emerged as an optimal solution in various industrial applications, particularly due to their compact design. One of the greatest advantages of this design is space optimization. Unlike traditional valves, wafer valves occupy significantly less space, making them ideal for installations where physical space is limited. Their slim profile allows for easy integration into existing systems without requiring extensive modifications, thus maintaining the efficiency of workflows in crowded environments.

Furthermore, the compact nature of wafer valves contributes to their lightweight characteristics, facilitating easier handling and installation. This not only reduces labor costs but also minimizes downtime during replacement or maintenance. Additionally, the streamlined design enhances fluid dynamics, leading to reduced pressure drops and improved flow rates. This means that industries can achieve optimal performance without the need for larger, more cumbersome equipment, ultimately leading to enhanced efficiency and reliability in operations.

This chart illustrates the top benefits of wafer valves in industrial applications, highlighting key areas such as space optimization, weight reduction, and cost efficiency, contributing to enhanced performance and operational efficiency.

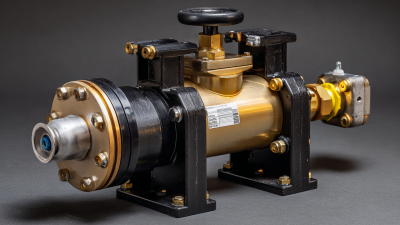

Wafer valves play a crucial role in optimizing fluid dynamics within industrial applications. Their compact design allows for streamlined flow paths, reducing turbulence and pressure drop compared to traditional bulkier valve types. This enhanced flow characteristic not only leads to improved efficiency in the conveyance of fluids but also minimizes energy consumption, which is critical in large-scale operations that often operate under tight budgets.

Wafer valves play a crucial role in optimizing fluid dynamics within industrial applications. Their compact design allows for streamlined flow paths, reducing turbulence and pressure drop compared to traditional bulkier valve types. This enhanced flow characteristic not only leads to improved efficiency in the conveyance of fluids but also minimizes energy consumption, which is critical in large-scale operations that often operate under tight budgets.

Moreover, wafer valves are designed to maintain optimal performance even under varying pressure conditions. Their lightweight structure and robust sealing capabilities ensure that they perform reliably, minimizing leakage and maximizing flow control. This increased precision in fluid management leads to smoother operations and can ultimately result in significant cost savings for industries reliant on efficient fluid handling systems. By prioritizing improved flow characteristics, wafer valves contribute significantly to the overall performance and effectiveness of industrial processes.

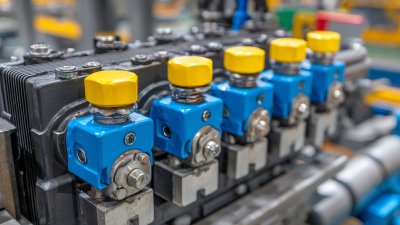

Wafer valves are increasingly recognized for their cost-effectiveness in industrial applications, making them a go-to choice for many businesses seeking to optimize their operations. Their compact design minimizes material use and manufacturing costs, leading to significant savings without compromising performance. This advantage is particularly noteworthy in large-scale operations where every dollar counts. Additionally, the reduced weight of wafer valves lowers installation and transportation costs, streamlining the entire supply chain.

**Tip:** When selecting wafer valves, consider their maintenance requirements. Opting for valves that require less frequent maintenance can lead to further cost savings over time.

Moreover, wafer valves offer ease of installation, allowing for quicker setup times in various systems. Their compatibility with a range of piping materials and sizes also enhances their versatility, ensuring that companies can adapt them to a variety of applications without incurring additional costs. The lower overall lifecycle cost associated with wafer valves means that companies can allocate resources more efficiently, enhancing their return on investment.

**Tip:** Conduct a thorough analysis of your system's needs before purchasing wafer valves to ensure you choose the most suitable option and maximize your cost benefits.

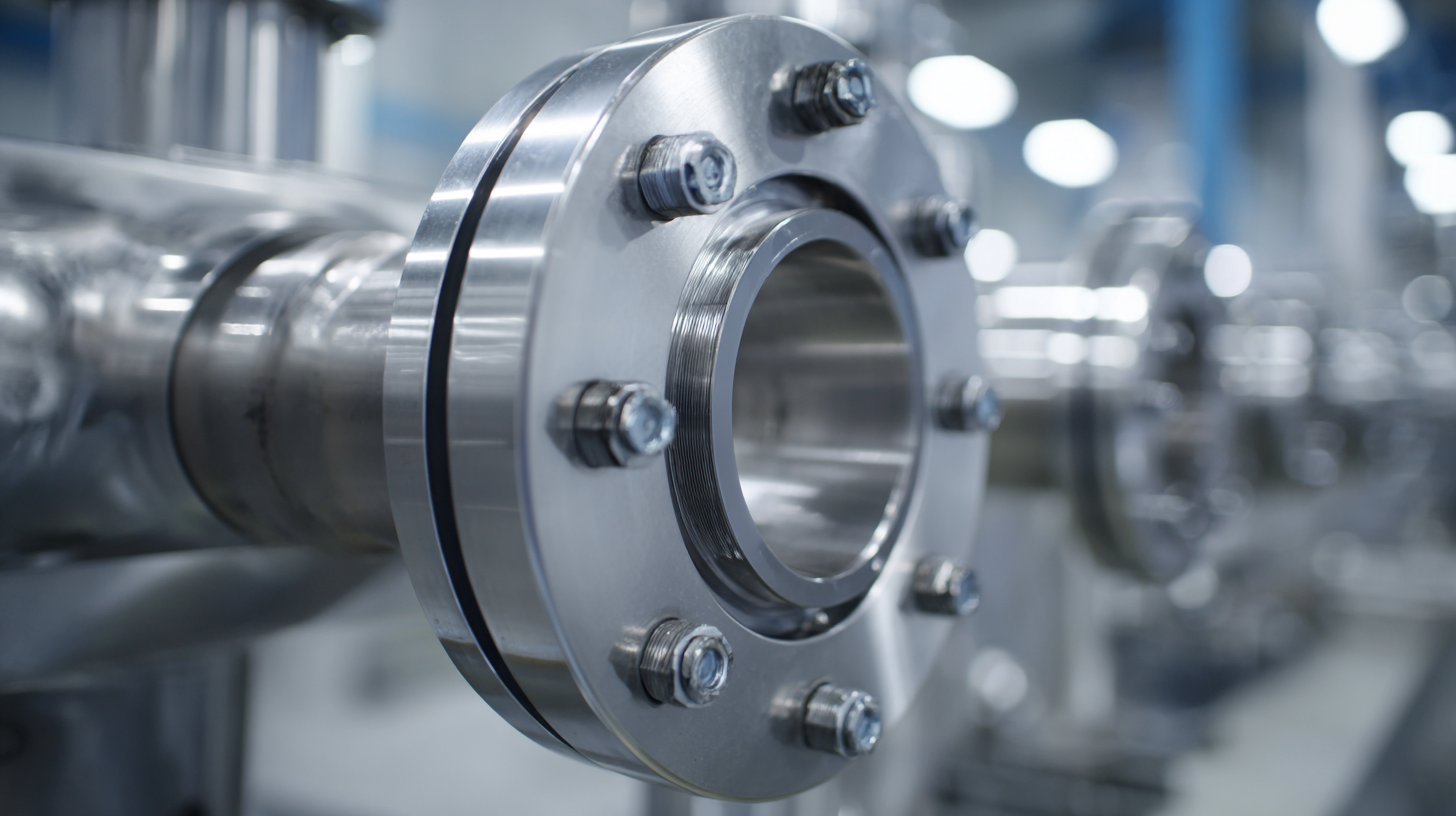

Wafer valves have gained widespread recognition in various industrial applications due to their outstanding durability and longevity. Unlike traditional valves, wafer valves feature a compact design that minimizes wear and tear during operation. The materials used in their construction, such as stainless steel and high-grade alloys, provide resistance to corrosion and temperature fluctuations, ensuring a longer lifespan. This robustness translates to reduced maintenance requirements, allowing industries to minimize downtime and improve overall productivity.

Tips for maintaining wafer valves include regular inspections to identify signs of wear or damage early on. Keeping the valve components clean and well-lubricated can significantly extend their service life. It’s also advisable to operate the valves within their specified pressure and temperature ranges to avoid unnecessary strain. Following these maintenance practices not only enhances the performance of wafer valves but also ensures they deliver efficient service over time.

In demanding industrial environments, selecting wafer valves contributes to both performance optimization and cost efficiency. Their durability means industries can focus more on production rather than valve upkeep, resulting in significant operational benefits. By investing in high-quality wafer valves, businesses can effortlessly enhance their efficiency while ensuring a reliable and long-lasting solution for fluid control systems.

Wafer valves have emerged as a versatile solution across various industries due to their efficiency, compact design, and weight advantages. The increasing demand for streamlined installations in HVAC systems reflects the industry's shift towards more innovative and adaptable valve technologies. Recent statistics indicate that the global butterfly valve market, a prominent category for wafer-style valves, was valued at approximately USD 11.3 billion in 2024, with projections to grow to USD 18.4 billion by 2034. This growth underscores the crucial role of wafer valves in enhancing fluid control and system performance in diverse applications.

The lightweight plastic designs of wafer-style butterfly valves, as opposed to traditional metal variants, are gaining traction, especially in sectors requiring stringent weight management and corrosion resistance. For instance, developments like the new comprehensive range of thermoplastic wafer valves are now capable of accommodating larger pipe dimensions, making them suitable for high-flow applications. As the Asia Pacific butterfly valve market continues to flourish, with manual butterfly valves accounting for over 55% of demand in 2024, it is evident that the industry is leaning towards efficient, high-performance solutions that offer both flexibility and enhanced operational efficiency.