The industrial automation sector is witnessing a transformative shift, with butterfly valve actuators emerging as pivotal components in enhancing operational efficiency. According to a report by MarketsandMarkets, the global actuator market is projected to reach USD 60.9 billion by 2025, with a notable increase in the adoption of smart valve actuators across various industries, including oil and gas, water and wastewater, and chemical processing. This growth is driven by the need for improved process control, reduced energy costs, and the integration of Industry 4.0 technologies. Butterfly valve actuators, recognized for their design simplicity and reliability, play a crucial role in this evolution by enabling rapid and precise control of fluid flow. As industries strive to optimize performance and reduce downtime, the implementation of these actuators is not just an operational upgrade but a strategic initiative that promises to propel productivity to new heights.

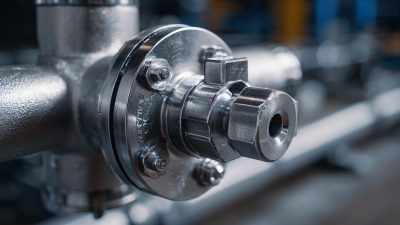

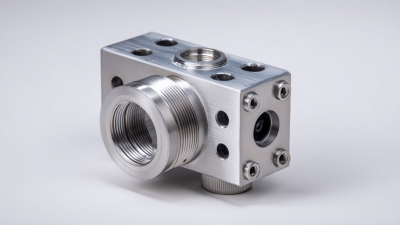

The rise of butterfly valve actuators marks a significant evolution in the realm of industrial control systems. Traditionally, industrial automation relied on a range of valve types and actuator mechanisms that often came with inherent limitations in terms of efficiency and responsiveness. Butterfly valves, with their streamlined design and lightweight construction, have emerged as a preferred choice for many industries, particularly in applications requiring rapid opening and closing cycles. The introduction of advanced actuators enhances their performance, ensuring precision control over fluid flow, which is critical in processes ranging from water treatment to chemical manufacturing.

Moreover, the integration of smart technologies within butterfly valve actuators has revolutionized monitoring and control capabilities. These devices can now be equipped with IoT connectivity, enabling real-time data collection and analysis. This capability allows operators to make informed decisions based on current system performance, predict maintenance needs, and optimize operational efficiency. With the continuous advancement of this technology, industries are not only witnessing improved reliability and safety but also significant reductions in energy consumption and operational costs, fundamentally transforming how industrial processes are managed.

The integration of butterfly valve actuators in industrial automation systems has brought about a significant transformation in efficiency and performance. As the global integrated marine automation system market is expected to grow from $6.1 billion in 2025 to $17.3 billion by 2035, with a compound annual growth rate (CAGR) of 11%, it's clear that automation is flourishing and driving demand for advanced components like actuators. These devices play a crucial role in optimizing operations by ensuring accurate control of fluid flow and enhancing system responsiveness.

Tips for improving automation system performance include considering the adoption of advanced actuator technologies that can align with evolving automation trends. The actuator market is predicted to expand significantly, influenced by advancements in robotics, artificial intelligence, and machine learning. Reports estimate that the robotic automation actuator market will increase from $4.6 billion in 2023 to $12.0 billion by 2032. Companies looking to stay ahead should prioritize integrating such innovative components to maximize operational efficiency.

Moreover, investing in modular and smart actuator systems can further enhance adaptability within industrial environments. The push for interconnected devices and systems emphasizes the importance of employing actuators that not only provide reliable control but also facilitate seamless communication across automated platforms, thereby driving greater efficiency and productivity in industrial settings.

In the evolving landscape of industrial automation, butterfly valve actuators are at the forefront of enhancing operational efficiency. Recent studies indicate that the global butterfly valve market is poised to reach $4.5 billion by 2028, driven largely by technological advancements in actuator design. The integration of smart electronics and real-time monitoring systems has significantly improved the operational capabilities of these valves, allowing industries to automate processes with unprecedented precision. As reported by MarketsandMarkets, the adoption of electric actuators in butterfly valves has increased by 35% over the past three years, highlighting a shift towards more energy-efficient and environmentally friendly solutions.

Additionally, advancements in materials and engineering technologies have led to the creation of more durable and lightweight butterfly valves. Innovations such as enhanced sealing technologies are reducing leakage rates, which, according to a recent report by the International Society of Automation, can save companies up to 20% in operational costs annually. Moreover, the development of modular actuator designs allows for easier integration into existing systems, reducing downtime and maintenance needs. These factors are critical in industries such as oil and gas, where efficiency and reliability are paramount, illustrating how butterfly valve actuators are revolutionizing the sector through cutting-edge design and engineering excellence.

The implementation of butterfly valve actuators has proven transformative for various industries, showcasing remarkable efficiency and reliability. One notable case study involves a chemical processing plant where traditional valve systems were replaced with electric actuators for butterfly valves. This transition led to a 30% reduction in energy consumption, significantly decreasing operational costs. Additionally, the new actuator systems provided enhanced precision in flow control, resulting in improved product quality and reduced waste.

In another instance, a wastewater treatment facility integrated pneumatic butterfly valve actuators into its operations. This change allowed for quicker response times and reduced maintenance downtime, as the actuators were engineered to withstand harsh environments and require less frequent servicing. The facility reported a marked increase in throughput, effectively managing larger volumes of wastewater while maintaining compliance with stringent environmental regulations. These successful implementations illustrate the versatile capabilities of butterfly valve actuators, enabling industries to operate more efficiently and sustainably.

The integration of AI technologies into butterfly valve actuators is setting new benchmarks for industrial automation. As industries strive for greater efficiency, AI's predictive analytics capabilities are enabling real-time performance monitoring and fault detection. According to a recent report by MarketsandMarkets, the global industrial automation market is projected to reach $296.7 billion by 2025, with AI-driven solutions playing a pivotal role in this growth. By leveraging machine learning algorithms, valve actuators can optimize their operations, reducing energy consumption by as much as 20%, thus directly impacting operational costs.

Furthermore, the implementation of AI in valve actuator systems allows for enhanced adaptability to changing operational parameters. Research from McKinsey & Company suggests that companies embracing AI in their processes can expect productivity increases of up to 30%. AI-driven actuators can learn from historical data patterns, enabling them to make autonomous adjustments in response to varying flow conditions and pressures. This not only minimizes wear and tear on equipment but also extends the lifespan of the actuators. As AI continues to evolve, butterfly valve actuators are set to become even more intelligent, ushering in a new era of efficiency in industrial processes.