In the landscape of industrial applications, the choice of valve can significantly influence operational efficiency and productivity. Among the various options available, the plug valve stands out for its simplicity and reliability in controlling the flow of liquids and gases. However, as industries evolve and demand for higher efficiency increases, it's crucial to explore top alternatives to the traditional plug valve. These alternatives not only enhance performance but also address the shortcomings often associated with plug valves, such as wear and maintenance challenges.

In this blog, we will delve into innovative valve solutions designed to optimize industrial processes, evaluating their features and advantages. By understanding these alternatives, industries can make informed decisions that drive enhanced efficiency and long-term sustainability.

In the quest for enhanced industrial efficiency, it’s essential to explore alternatives to traditional plug valves. These alternatives can offer significant advantages that cater to the unique needs of various applications. One key reason to consider switching is their improved flow control. Many alternatives, such as ball and butterfly valves, provide better throttling capabilities, allowing for precise adjustments in flow rates, which can lead to more efficient operations in large-scale processes.

Another benefit of exploring alternatives is their superior sealing performance. Unlike plug valves, which may wear out and require replacement over time, options like globe valves and gate valves can maintain tighter seals, minimizing the risk of leaks and enhancing reliability. This not only improves safety but also reduces maintenance costs, contributing to an overall reduction in downtime.

Lastly, the diverse range of materials available for these alternatives enables customization based on specific environmental conditions, thereby increasing longevity and performance in various operational settings.

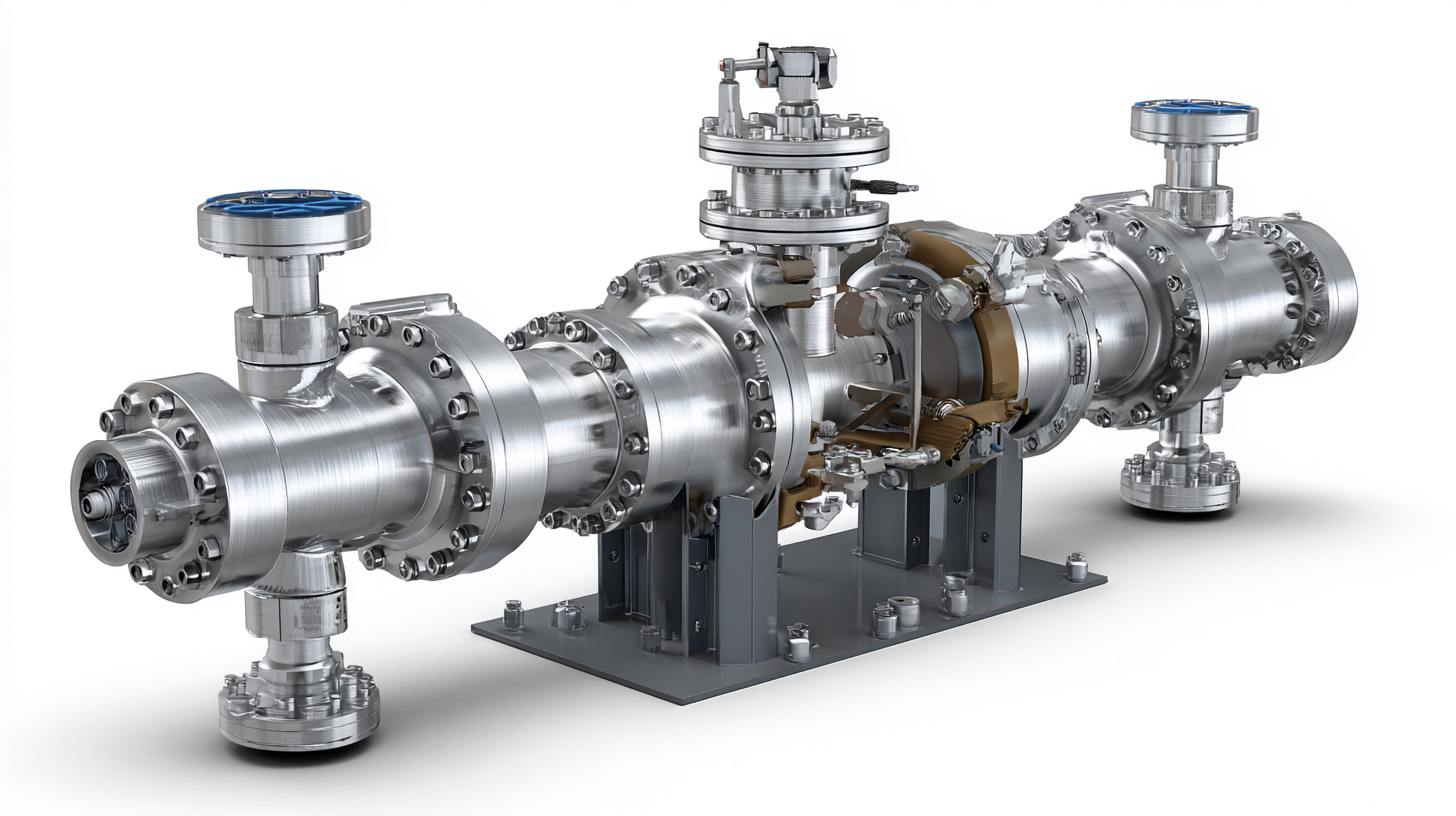

In the quest for industrial efficiency, evaluating valve technologies is paramount. While plug valves have long been favored for their straightforward design and reliable sealing capabilities, exploring alternatives can reveal significant efficiency gains in various applications. Technologies such as ball valves, butterfly valves, and diaphragm valves present unique advantages that may better suit specific operational requirements. For instance, ball valves offer lower flow resistance and faster operation, which can enhance system performance, particularly in high-pressure applications. Their compact size also allows for streamlined installation, making them an attractive alternative.

Butterfly valves, on the other hand, shine in scenarios where space is limited, thanks to their lightweight design and quick actuation. They are particularly efficient for large-scale flow control, enabling rapid response times and reduced energy consumption. Additionally, diaphragm valves provide excellent control over corrosive fluids, ensuring longevity and reducing maintenance needs. This comparative analysis highlights that by understanding the specific demands of industrial applications, operators can make informed choices that not only optimize performance but also contribute to overall operational efficiency. Embracing alternative valve technologies can pave the way for enhanced productivity in today's competitive industrial landscape.

This chart compares the efficiency gains of various valve technologies used in industrial applications. The data indicates the percentage improvement in efficiency relative to standard plug valves.

Cost-effectiveness has become a significant concern for industries aiming to optimize their operational expenses. Recent studies, such as the "2023 Valve Market Report", indicate that businesses can reduce their operational costs by up to 20% by transitioning from traditional plug valves to alternative valve technologies like ball valves or butterfly valves. These alternatives not only provide similar functionality but also enhance reliability and efficiency in flow control, leading to improved overall operational performance.

Additionally, industries utilizing advanced valve solutions have reported decreased maintenance costs. The valve maintenance cost in industrial settings can reach up to 15% of the total maintenance budget. By switching to options such as automated ball valves with fewer moving parts, companies have successfully minimized their maintenance issues, further driving down costs. A survey conducted by the "International Society of Automation" found that 70% of companies that adopted modern valve technologies saw noticeable reductions in both maintenance frequency and associated costs. These compelling statistics highlight the financial advantages of reevaluating traditional valve choices and exploring innovative alternatives for enhanced industrial efficiency.

In high-pressure environments, the performance of valves is critical for maintaining efficiency and safety within industrial processes. While traditional plug valves have been widely used, alternative valve types offer distinct advantages that can significantly enhance operational performance. One major area where these alternatives excel is in reducing pressure drop. For instance, ball valves and butterfly valves provide smoother flow paths with less turbulence, resulting in lower resistance and improved flow rates, which is vital in high-pressure applications.

Another performance metric to consider is durability under extreme conditions. Many alternative valves, such as check valves and globe valves, are designed with materials and mechanisms that better withstand the wear and tear associated with high-pressure environments. This durability translates to longer service life and less frequent replacements, reducing overall maintenance costs. Furthermore, these alternatives often feature advanced sealing mechanisms that minimize leaks, ensuring operational integrity and reliability over time.

Lastly, the versatility of alternative valves should not be overlooked. While traditional plug valves may be limited in their applications, newer designs allow for greater adaptability to various fluid types and operational demands. Whether it's handling corrosive substances or accommodating fluctuating pressure levels, alternative valves are engineered to optimize performance across a range of industrial scenarios, making them an invaluable choice for enhancing efficiency in high-pressure environments.

| Valve Type | Material | Pressure Rating (psi) | Temperature Range (°F) | Flow Coefficient (Cv) | Operational Efficiency (%) |

|---|---|---|---|---|---|

| Ball Valve | Stainless Steel | 6000 | -40 to 450 | 250 | 95 |

| Gate Valve | Carbon Steel | 3000 | -20 to 400 | 300 | 90 |

| Butterfly Valve | PVC | 150 | -10 to 180 | 400 | 85 |

| Check Valve | Bronze | 2000 | 0 to 200 | 150 | 92 |

In today's industrial landscape, the demand for reliable and efficient valve systems is paramount. Although conventional plug valves have been a staple in various applications, alternative valve options are increasingly gaining traction due to their extended lifespans and reliability. Reports indicate that alternatives such as ball valves and butterfly valves can exhibit service lives that are up to 25% longer compared to traditional plug valves. This longevity often translates into reduced maintenance costs and minimized operational downtime, making them a compelling choice for industries focused on enhancing efficiency.

Moreover, the integration of advanced materials and designs is further propelling the development of these alternatives. For instance, the use of corrosion-resistant alloys and composite materials allows for superior performance under extreme conditions, which is essential in sectors like oil and gas, where mechanical wear can be significant. By choosing the right valve type, industries not only ensure durability but also optimize their operations.

Tips: When selecting a valve, consider the specific application requirements, such as temperature fluctuations and fluid type, to ensure compatibility. Regular maintenance schedules can also help extend valve lifetime and performance. Lastly, investing in technologies like predictive maintenance powered by AI can streamline operations and enhance industrial efficiency significantly.