In the realm of industrial applications, the pneumatic ball valve stands out as a vital component for efficient fluid control systems. Understanding the mechanism and benefits of pneumatic ball valves is crucial for engineers and technicians looking to optimize operations in various sectors, including manufacturing, oil and gas, and chemical processing. These valves are renowned for their robust design, optimal flow characteristics, and rapid actuation capabilities, which contribute to their widespread adoption. In this guide, we will explore the fundamental principles behind pneumatic ball valves, how they operate, and the numerous advantages they offer in terms of performance, reliability, and maintenance. By delving into these aspects, we aim to provide a comprehensive understanding that will assist industry professionals in making informed decisions about implementing pneumatic ball valves in their systems.

Pneumatic ball valves are an essential component in numerous industrial applications,

renowned for their reliability and efficiency. These valves operate utilizing

compressed air to drive a ball with a bore through which fluid can flow. The unique

mechanism of pneumatic actuators allows for rapid opening and closing,

providing precise control over fluid dynamics. According to

a report by MarketsandMarkets, the global pneumatic valve market is projected to grow from

$3.5 billion in 2020 to $5.1 billion by 2025, highlighting

the increasing adoption of pneumatic systems across industries such as oil and gas, chemicals,

and pharmaceuticals.

Pneumatic ball valves are an essential component in numerous industrial applications,

renowned for their reliability and efficiency. These valves operate utilizing

compressed air to drive a ball with a bore through which fluid can flow. The unique

mechanism of pneumatic actuators allows for rapid opening and closing,

providing precise control over fluid dynamics. According to

a report by MarketsandMarkets, the global pneumatic valve market is projected to grow from

$3.5 billion in 2020 to $5.1 billion by 2025, highlighting

the increasing adoption of pneumatic systems across industries such as oil and gas, chemicals,

and pharmaceuticals.

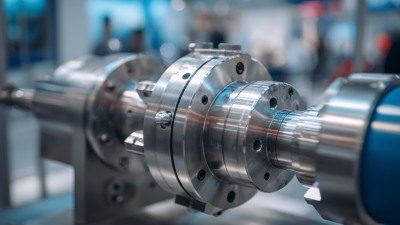

In operation, the pneumatic ball valve consists of a valve body, a ball, and pneumatic actuators,

which control the rotation of the ball. When the actuator receives a signal, it generates thrust,

rotating the ball to either allow or prevent the flow of fluid. The high-speed actuation associated

with pneumatic systems—with response times often below 1 second—makes these

valves ideal for processes requiring agility and precision. Furthermore, due to their

compact design and minimal maintenance requirements, they play a pivotal role in enhancing

operational efficiency, as noted in a recent IEC Report that highlights a 25% reduction in downtime

for facilities utilizing pneumatic ball valve technology.

Pneumatic ball valves are increasingly preferred in industrial applications due to their robust performance and reliability. One of the key advantages is their ability to provide quick and reliable shut-off in high-pressure systems. According to a report by the International Society of Automation (ISA), pneumatic valves can respond to control signals within seconds, significantly reducing operating times in automated processes. This rapid response ensures minimal downtime, thereby enhancing overall productivity in manufacturing environments.

Moreover, pneumatic ball valves offer superior flow control, making them ideal for handling various media, including gases and liquids. A study by the Flow Control Association noted that these valves maintain consistent flow rates and pressure drops, leading to energy savings of up to 30% in fluid transport systems. Their inherent design allows for fewer moving parts compared to other valve types, which reduces maintenance needs and extends lifespan, further boosting their appeal in industrial settings. This combination of performance, efficiency, and reliability positions pneumatic ball valves as a strategic choice for industries aiming to optimize their operations.

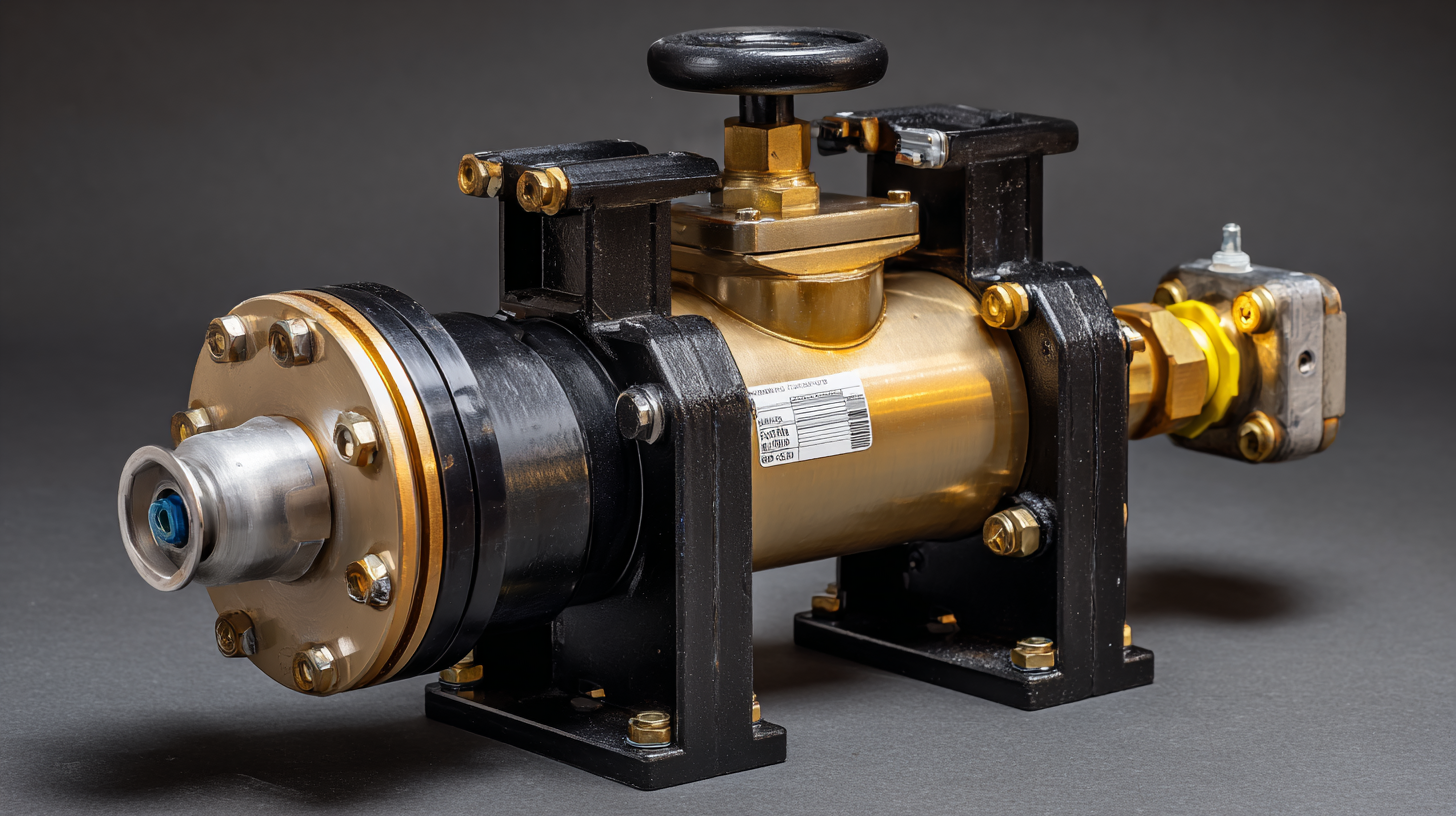

When selecting pneumatic ball valves for industrial applications, several key factors need careful consideration to ensure optimal performance and reliability. First, the valve size and flow characteristics should match the specific requirements of the system. According to the Fluid Control Institute, correct sizing can lead to improved efficiency and reduced energy costs by as much as 20%. Additionally, the materials of construction must withstand the operating conditions, including temperature, pressure, and the nature of the media being controlled. For instance, valves made from stainless steel are ideal for corrosive substances, while those with PTFE lining can handle extreme temperature variations.

Tips: Always consult with a valve specialist to evaluate the compatibility of materials with the fluids involved. This can prevent costly downtime and ensure longevity in harsh operating environments.

Another critical aspect is the actuator type. Pneumatic actuators provide rapid response and high reliability, making them suitable for applications requiring quick on-off control. Reports suggest that pneumatic systems can operate effectively in environments with ambient temperatures ranging from -20°C to +80°C. Ensure that your pneumatic ball valve's actuator is rated for the operating conditions to maximize performance and minimize failure rates.

Tips: Consider implementing a maintenance schedule that includes regular checks on actuator performance to prolong the service life of your pneumatic ball valves. This proactive approach can save time and reduce the risk of unexpected interruptions in production.

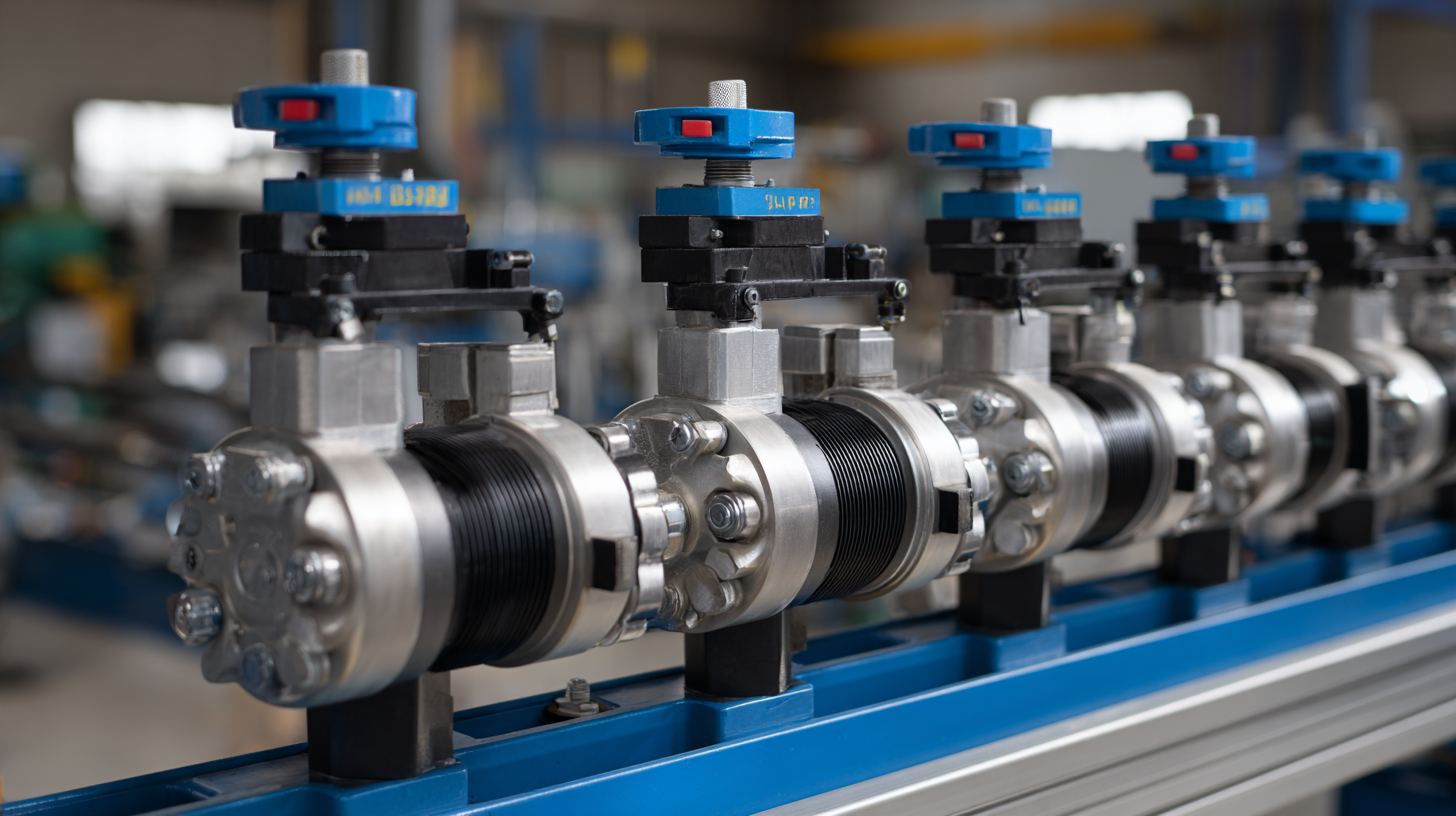

Pneumatic ball valves have gained popularity in industrial applications due to their efficiency and reliability. When compared to other valve types, such as gate, globe, and butterfly valves, pneumatic ball valves offer several advantages. They provide a full flow capacity, minimizing pressure drops and ensuring optimal fluid transfer. Their quick-action mechanism allows for rapid opening and closing, making them ideal for processes that require high responsiveness. Additionally, the sealing performance of pneumatic ball valves reduces leaks, which is critical in maintaining system integrity.

Tips: When choosing a valve type, consider the specific application requirements such as flow rate, pressure conditions, and the nature of the fluids being handled. Pneumatic ball valves are particularly effective in high-pressure and high-temperature environments.

In contrast to gate valves, which can suffer from slow operation and wear over time, pneumatic ball valves maintain a longer service life and require less maintenance. Unlike globe valves, which are often constrained by a limited flow area, pneumatic ball valves facilitate unrestricted fluid movement, leading to increased operational efficiency. For applications that demand quick cycling, the responsiveness of pneumatic ball valves can significantly enhance overall system performance.

Tips: Regular maintenance checks on pneumatic systems can further prolong the lifespan of the valves and prevent unexpected downtimes. Always evaluate the integration of pneumatic ball valves in your process for maximum efficacy.

To ensure optimal performance of pneumatic ball valves, regular maintenance is crucial. One of the primary maintenance tips is to frequently inspect the valve's seals and gaskets. Over time, exposure to pressure fluctuations and environmental conditions can lead to wear and deterioration, causing leaks that affect overall system efficiency. Regular visual inspections can help identify any signs of degradation early, allowing for timely replacements before major issues arise.

Another essential maintenance practice is to check the actuator's function, as it directly influences the valve's performance. Lubricating moving parts, such as rods and bearings, can prevent friction and ensure smooth operation. Additionally, it's important to verify that pneumatic connections are secure and free from obstructions. Periodic testing of the system under operational conditions can also help in assessing the valve's responsiveness and alignment, ensuring that it can operate effectively when called upon in critical industrial applications. Consistent monitoring and upkeep will not only extend the lifespan of pneumatic ball valves but also enhance the reliability of the entire system.