In the realm of industrial applications, the selection of the appropriate butterfly valve actuator is crucial for ensuring operational efficiency and reliability. The butterfly valve actuator plays a pivotal role in controlling the flow of fluids, thereby impacting the overall performance of piping systems. However, with a myriad of options available in the market, identifying the right actuator can be a daunting task for engineers and procurement specialists alike.

This guide aims to demystify the process of selecting a butterfly valve actuator by outlining the key factors to consider and presenting a curated list of the "Top 10" actuators currently available. By exploring aspects such as compatibility, actuator type, response speed, and maintenance requirements, this comprehensive resource will equip decision-makers with the necessary knowledge to make informed choices that meet their unique operational needs. Ultimately, understanding the intricacies of butterfly valve actuators not only enhances process efficiency but also optimizes resource utilization across various applications.

Butterfly valve actuators play a crucial role in enhancing system efficiency across various industrial applications. By providing quick and precise control over fluid flow, these actuators significantly reduce response times in automated systems. This responsiveness is essential in processes where maintaining specific flow rates is critical, such as in water treatment plants or chemical processing facilities. The ability to modulate flow effectively minimizes energy consumption, leading to a more sustainable operation and lower operational costs.

Moreover, butterfly valve actuators can be integrated with advanced control systems that enable real-time monitoring and adjustments. This integration allows for optimal performance even in fluctuating conditions, ensuring that systems operate at peak efficiency. The simplicity of design in butterfly valves means that they require less maintenance, further contributing to overall system reliability. By selecting the right actuator, users can not only enhance the functionality of their butterfly valves but also significantly improve their systems' operational efficiency and longevity.

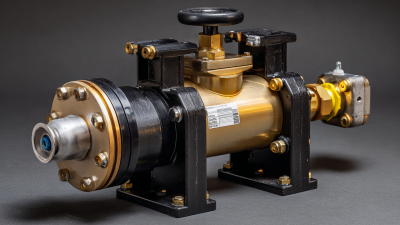

When selecting a butterfly valve actuator, several key factors must be considered to ensure optimal efficiency and performance. Begin by evaluating the actuator type—electric, pneumatic, or hydraulic—as each has distinct advantages. Electric actuators offer precision and control but may require more maintenance, while pneumatic and hydraulic options provide rapid response times.

Tips: Always align the actuator’s specifications with your system's requirements. Understanding the torque needed for your specific application is crucial in ensuring the actuator operates effectively without underperformance or wear.

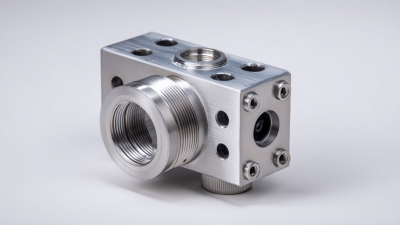

Another important factor is the actuator's environment. Consider the operating conditions such as temperature, humidity, and any potential exposure to corrosive substances. Choosing an actuator designed to withstand these conditions will prolong its lifespan and maintain efficiency.

Tips: When in doubt, consult manufacturer guidelines or industry standards to find an actuator that will not only fit your current needs but also adapt to future operational changes. It's essential to balance initial costs with long-term performance and maintenance requirements to maximize overall efficiency.

When it comes to selecting the right actuator for butterfly valves, it's essential to understand the differences between electric, pneumatic, and hydraulic options. Each type of actuator offers unique advantages suited to specific operational needs. For instance, electric actuators are known for their precise control and energy efficiency. According to a report by Research and Markets, the global electric actuator market is expected to reach $11.42 billion by 2026, growing at a CAGR of 7.1%. This growth can be attributed to the increasing demand for automated systems and energy savings in industries such as oil and gas, water supply, and manufacturing.

On the other hand, pneumatic actuators are preferred in applications requiring rapid movement and high thrust. They operate using compressed air, allowing for swift opening and closing of valves. The Pneumatics & Fluid Power Report highlights that pneumatic actuators can achieve response times of less than a second, making them ideal for processes that require quick modulation. Moreover, their simplified design often results in lower maintenance costs, contributing to their popularity in high-speed industrial settings.

Hydraulic actuators, while generally more complex, deliver immense power and torque, making them suitable for heavy-duty applications. They are widely utilized in industries like construction and marine, where high force is necessary. A study by the Hydraulic Institute indicates that advancements in hydraulic technology are driving efficiency improvements, leading to a 20% reduction in energy consumption for certain applications. Thus, when choosing the right actuator for butterfly valves, one must consider the specific requirements of the application, efficiency needs, and the desired speed of operation.

| Actuator Type | Energy Source | Control Range | Response Time | Installation Complexity | Cost | Maintenance |

|---|---|---|---|---|---|---|

| Electric | Electricity | Wide | Fast (milliseconds) | Moderate | Moderate | Low |

| Pneumatic | Compressed Air | Moderate | Very Fast (milliseconds) | Low | Low to Moderate | Moderate |

| Hydraulic | Hydraulic Fluid | Narrow | Slow to Moderate | High | High | High |

Butterfly valve actuators play a crucial role in the effective control of fluids across various industries, including water treatment, chemical processing, and HVAC systems. According to a recent study by the International Society of Automation, the global butterfly valve actuator market is projected to reach $2.5 billion by 2026, reflecting a compound annual growth rate of over 6%. This growth underscores the importance of selecting the right actuator for specific applications to enhance operational efficiency.

In water treatment facilities, electric actuators are increasingly favored for their precision and ease of integration with automated control systems. Reports indicate that using electric actuators can reduce energy consumption by up to 30% compared to pneumatic models, making them a sustainable choice for facility operations. In chemical processing, the demand for fail-safe actuators has surged, driven by regulatory requirements for safety and reliability. Data from the American National Standards Institute shows that companies prioritizing robust actuator designs can reduce operational downtimes by up to 40%, significantly impacting productivity and cost savings. Thus, understanding the application requirements and actuator types is essential for optimizing performance in these critical sectors.

When it comes to maintaining and troubleshooting butterfly valve actuators, understanding the common issues and their solutions can significantly enhance operational efficiency. According to a report by the Valve Manufacturer's Association, approximately 30% of all valve failures stem from actuator malfunctions. Regular maintenance can prevent these failures and prolong the lifespan of the equipment.

One crucial tip is to schedule routine inspections every six months. During these inspections, check for any signs of wear on the actuator components and ensure that all connections are secure. This proactive approach not only catches problems early but also reduces the risk of unexpected downtime. Additionally, it’s essential to monitor the actuator’s performance parameters, such as response time and stroke position accuracy, to identify deviations that may indicate underlying issues.

In troubleshooting, remember to use a systematic approach. If a valve actuator is unresponsive, first check the power supply, as electrical issues are a common cause of malfunction. According to industry standards, a well-maintained actuator should have a response time within ±5% of its specified range. If the actuator does not meet this criterion, delve deeper into other components such as the pneumatic supply or control signals to find the root cause of the problem.