In the ever-evolving landscape of modern industrial applications, the demand for reliable and efficient control mechanisms has never been greater. Globe valves have emerged as a crucial component in managing fluid flow, offering significant advantages in both efficiency and durability. According to a recent industry report by the Valves and Actuators Market Research Group, the global market for globe valves is projected to grow at a CAGR of 5% over the next five years, driven by increased adoption in sectors such as oil and gas, water treatment, and power generation. These valves not only provide precise throttling capabilities but also exhibit exceptional durability under diverse operating conditions. As industries strive for enhanced performance while ensuring cost-effectiveness, understanding the operational efficiencies and long-term viability of globe valves becomes paramount, thereby underscoring their importance in achieving optimal system functionality.

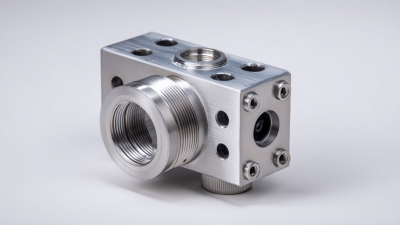

Globe valves play a crucial role in enhancing industrial efficiency by providing precise flow control and superior throttling capabilities in various applications. Their design, which includes a spherical body shape, allows for greater fluid regulation compared to other valve types. This feature is particularly beneficial in processes that require fine adjustments in flow rates, ensuring optimal performance and energy savings in industrial systems.

**Tips:** When selecting globe valves, consider factors such as the required flow rate and pressure drop within your specific system. Additionally, regular maintenance checks can help prevent wear and tear, extending the lifespan of the valves and maintaining system efficiency.

Moreover, the durability of globe valves is essential in high-demand environments. They are engineered to withstand significant pressure and temperature variations, making them suitable for applications in oil and gas, chemical processing, and water treatment. Implementing high-quality materials and coatings can further enhance their longevity, contributing to reduced downtime and operational costs.

**Tips:** Always inspect the valve seats and seals during maintenance to ensure a tight seal, which is vital for maintaining efficiency and preventing leaks. Properly sized actuators also play a key role in enhancing the valve's performance and lifespan.

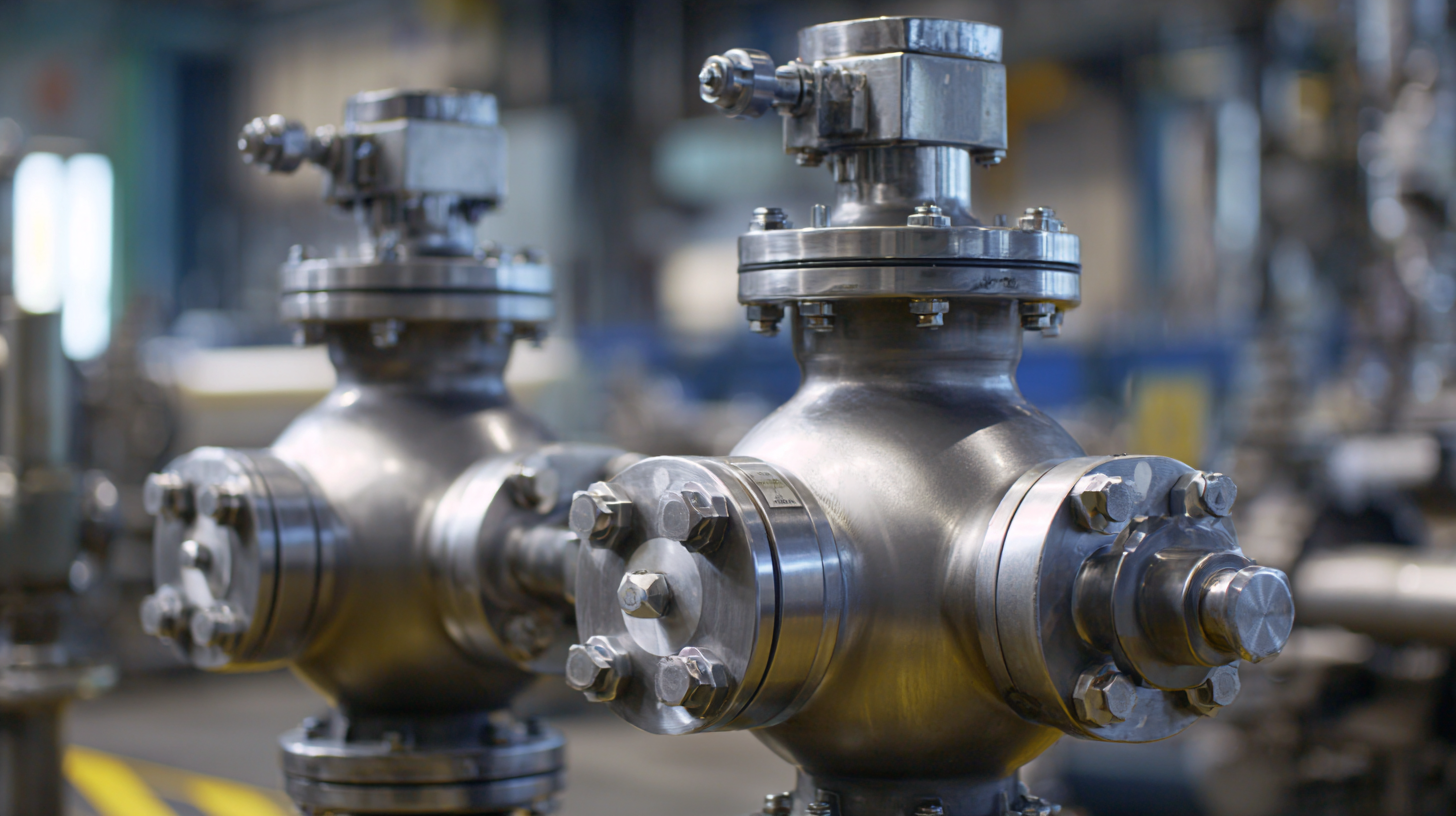

Globe valves are essential in various industrial applications due to their efficiency in regulating flow and durability under high-pressure conditions. One of the top applications of globe valves is in the oil and gas sector, where they play a critical role in controlling the flow of liquids and gases during extraction and processing. Their design allows for fine adjustments, making them ideal for precise control in complex pipeline systems.

Another significant application is in the power generation industry, where globe valves manage steam and water flow within boilers and turbines. Their ability to withstand extreme temperatures and pressures ensures reliable operation, which is crucial for maintaining efficiency and safety in energy production. Additionally, in the chemical processing industry, globe valves are used to handle corrosive substances, offering longevity and reducing the need for frequent replacements, thus enhancing operational efficiency.

This chart illustrates the distribution of globe valve applications across various industrial fields, highlighting their efficiency and durability.

When evaluating globe valves for modern industrial applications, understanding the key performance metrics for durability is essential. Globe valves are designed to regulate flow, and their effectiveness relies significantly on the materials used for construction and design specifications. Key performance metrics include pressure rating, temperature tolerance, and the ability to withstand corrosion and erosion. Valves must not only perform under high pressures but also endure fluctuating temperatures without compromising their integrity.

Tip: Always choose globe valves that meet or exceed industry standards for pressure and temperature requirements. This ensures reliability and longevity in demanding environments.

Additionally, regular maintenance and inspection schedules should be established to monitor valve performance over time. Wear and tear can lead to inefficiencies, and identifying issues early can mitigate the impact on operations. Assessing the metrics of materials, such as tensile strength and fatigue resistance, can also provide insights into the expected lifespan of the valves under normal operating conditions.

Tip: Implement predictive maintenance strategies that utilize sensor technology to monitor valve performance in real-time. This proactive approach can enhance the durability and operational efficiency of your globe valves.

Globe valves are essential components in many industrial processes, known for their ability to regulate flow rates effectively. However, their efficiency is deeply tied to proper maintenance practices. Regular inspections, as indicated by industry research, show that routine maintenance can extend the operational life of globe valves by up to 30%. This is critical as industries increasingly rely on optimizing productivity to maintain competitive advantages. Keeping valves clean and ensuring seals are intact can prevent leaks and pressure drops, thus maintaining system integrity.

Additionally, employing predictive maintenance strategies, such as using instrumentation and analytics to monitor valve performance, can further enhance durability. In a recent report, companies that invested in advanced analytics for valve maintenance reported a 20% improvement in asset availability and reduced downtime. Implementing these strategies not only minimizes unexpected failures but also leads to significant savings in repair costs and operational disruptions. By prioritizing the maintenance of globe valves, industries can ensure sustained efficiency and reliability in their processes.

In the industrial sector, the selection of valve types plays a crucial role in optimizing system performance and maintaining operational efficiency. Globe valves, renowned for their ability to regulate flow effectively, are particularly important in applications requiring precise control. When compared to other valve types, such as ball and butterfly valves, globe valves offer distinct advantages, particularly in high-pressure and high-temperature environments. Their design allows for fine throttling capabilities which are essential in processes where fluid dynamics are critical.

Moreover, the durability of globe valves in demanding industrial applications enhances their appeal. While ball valves are often preferred for on/off control due to their low resistance to flow, globe valves' robust construction and sealing capabilities make them ideal for sustaining longer service life under continuous operation. The ongoing evolution of the global industrial valves market, projected to witness substantial growth driven by advancements in materials and technology, further solidifies the relevance of globe valves alongside other types. Understanding these comparative dynamics aids industries in making informed decisions that align with their operational goals.