When it comes to optimizing fluid control systems, selecting the appropriate electric ball valve is crucial for achieving operational efficiency and reliability. According to a report by MarketsandMarkets, the electric valve market is projected to grow to USD 3.7 billion by 2025, driven by increasing automation in various industrial sectors.

Electric ball valves, known for their quick operation and precise flow control, have become a preferred choice in applications ranging from water treatment to oil and gas industries. Understanding the specific requirements of your application—such as temperature, pressure, and flow rate—is vital when choosing the right electric ball valve.

This decision not only affects system performance but also influences maintenance costs and longevity of the entire fluid control system. Making an informed choice can lead to enhanced efficiency and reduced downtime, ultimately impacting your bottom line.

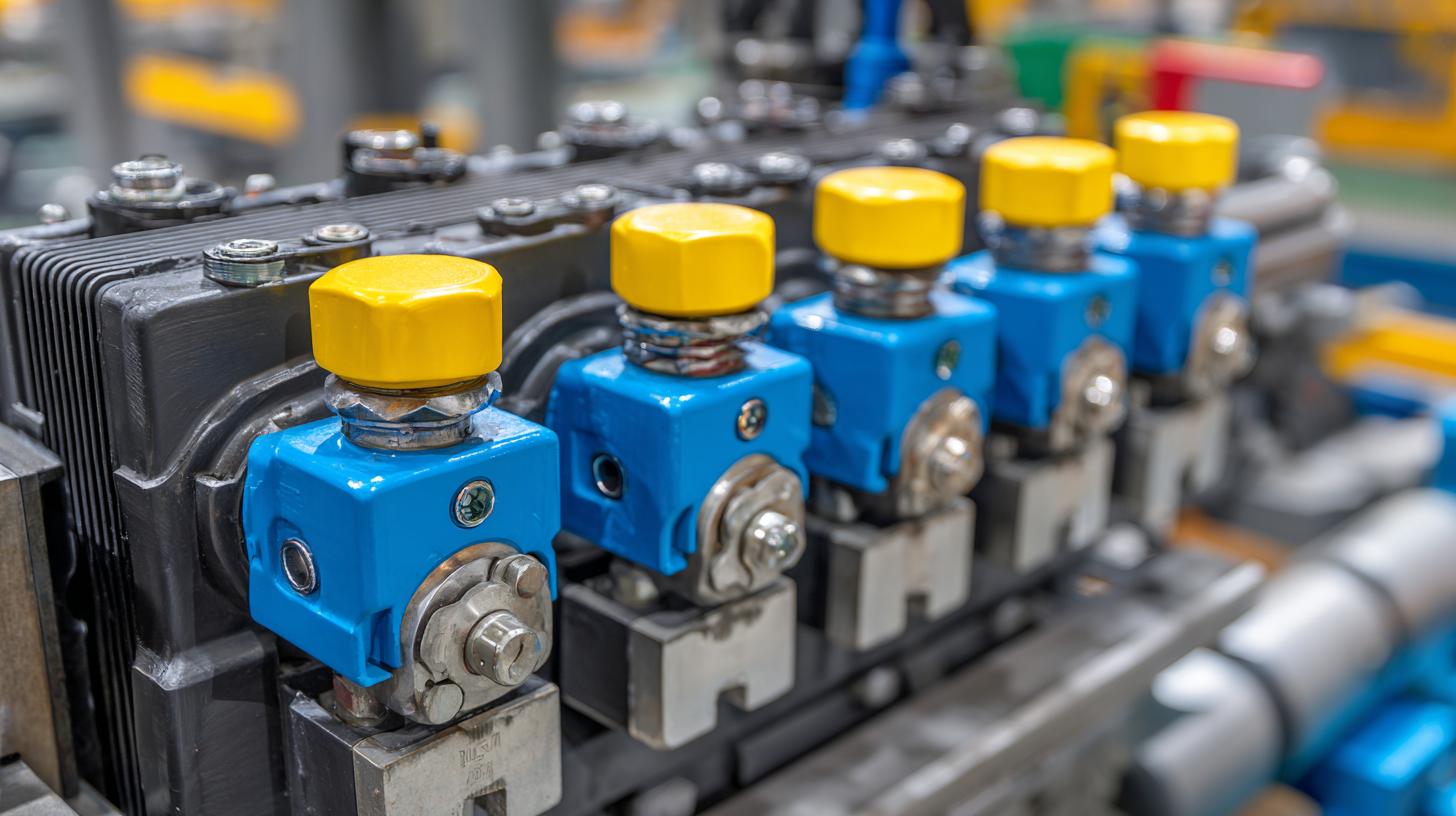

Electric ball valves are essential components in various industrial applications, and understanding their types and features is crucial for selecting the right valve. The most common types include two-way and three-way electric ball valves.

Two-way valves control the flow of fluid in a single direction, making them suitable for straightforward applications, such as shut-off processes. In contrast, three-way valves provide more versatility, allowing for mixing or diverting flow between two paths, which is particularly beneficial in systems requiring precise fluid control.

Two-way valves control the flow of fluid in a single direction, making them suitable for straightforward applications, such as shut-off processes. In contrast, three-way valves provide more versatility, allowing for mixing or diverting flow between two paths, which is particularly beneficial in systems requiring precise fluid control.

When selecting an electric ball valve, it is vital to consider specific features such as valve size, body material, and actuator type. The size of the valve must match the flow requirements of the application, while the body material—commonly brass, stainless steel, or plastic—should be chosen based on the fluid being transported and environmental conditions. Additionally, actuator types vary from simple on/off options to more advanced models with modulating capabilities, enabling fine control over flow rates.

Understanding these attributes ensures that you choose an electric ball valve that meets your operational needs efficiently.

When selecting an electric ball valve, assessing its compatibility with your existing system is crucial. The key factors to consider include the valve's voltage, control signal type, and actuation method. According to a recent market study by Valin Corporation, nearly 30% of system failures can be traced back to improper valve selection, emphasizing the importance of precision in compatibility evaluation. For instance, if your system utilizes 24VDC for control, opting for a valve designed for 120VAC could lead to significant operational issues or even equipment damage.

Another critical aspect is the valve's size and flow capacity. The American National Standards Institute (ANSI) has established flow coefficients (Cv) that range dramatically among different valves, which helps in ensuring that the selected valve can handle the flow requirements of your application. It's vital to match the valve’s technical specifications with your system's requirements to avoid performance bottlenecks. Ensuring the right match can increase energy efficiency by 20-30%, as noted in a recent energy efficiency report by the U.S. Department of Energy, highlighting the financial and operational benefits of making informed choices in valve selection.

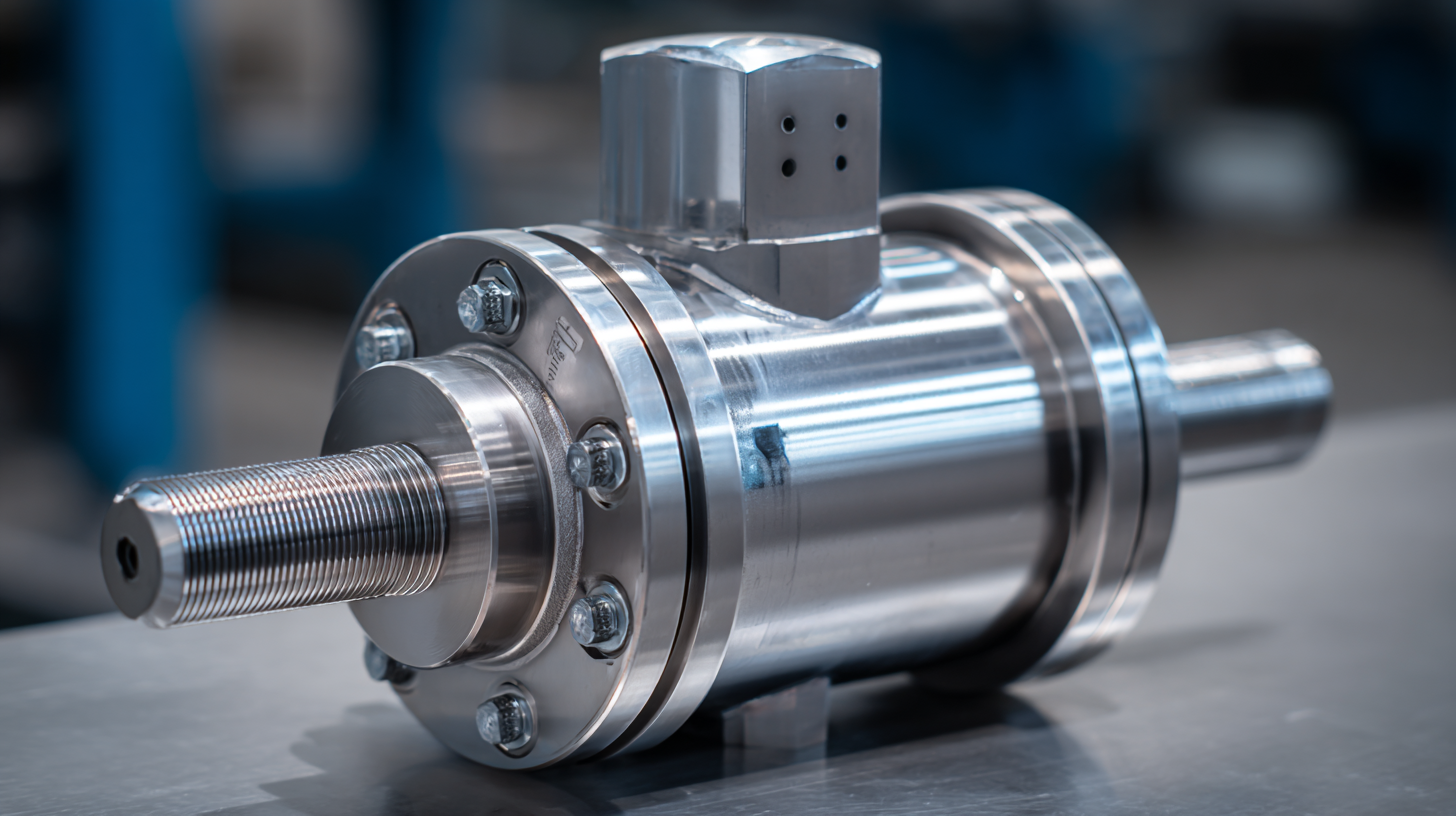

When selecting the right electric ball valve for your application, it is crucial to consider key technical specifications that ensure optimal performance. First, you should evaluate the valve's size and flow capacity, as these parameters dictate the efficiency of your system. Proper sizing prevents pressure drops and ensures adequate flow rates. Check the valve’s Cv rating, which measures the flow capacity, to match it with the requirements of your specific application.

Additionally, the material of the valve body and components plays a vital role in the valve's performance. The choice of materials can affect resistance to corrosion, temperature fluctuations, and pressure changes. For instance, stainless steel is often preferred in applications requiring durability and resistance to aggressive media. Furthermore, it is essential to assess the actuator's power requirements, response time, and control options to ensure that the electric ball valve can efficiently integrate with your existing control systems. Consideration of these specifications can lead to improved performance and longevity of the valve in your specific application.

When it comes to selecting the appropriate electric ball valve for your project, proper sizing and configuration are pivotal. According to a recent report by the Valve Manufacturers Association, improperly sized valves can lead to inefficiencies, with potential pressure drops reaching up to 30% in certain applications. This underlines the importance of accurate flow rate calculations based on the system's requirements. Additionally, the configuration—whether it’s a normally open or normally closed valve—should be carefully considered in relation to your process dynamics.

Tips: To determine the right size, always refer to the manufacturer’s flow coefficient (Cv) data, which indicates the valve's capacity to allow fluid to pass. Use this alongside specific system requirements—such as pressure, temperature, and fluid characteristics—to ensure compatibility. Ensure that your chosen valve can handle the maximum expected flow rate comfortably.

Furthermore, specialized applications may require tailored configurations, such as modulating control valves that facilitate precise flow adjustments. The International Society of Automation reports that optimizing valve configurations in processes can improve overall system performance by up to 25%, significantly reducing energy consumption over time. Make sure to evaluate the control strategy and the operational environment to select an electric ball valve that not only fits but enhances your system’s functionality.

When selecting the right electric ball valve for your specific application, it's crucial to evaluate factors such as cost, reliability, and maintenance needs. According to the 2022 Market Research Report on Industrial Valves, electric ball valves account for approximately 25% of the global valve market, a testament to their growing importance in various industries due to their efficiency and precision. The initial cost of electric ball valves typically ranges from $50 to $500 depending on size, material, and features. However, it's essential to consider the long-term operational efficiency and potential savings in energy and maintenance costs that these valves provide.

Reliability is another essential aspect when choosing an electric ball valve. A recent study by the Valve Manufacturers Association indicated that electric ball valves have a failure rate as low as 2% when properly maintained, significantly lower than many mechanical alternatives. This reliability translates into reduced downtime and maintenance costs, which can be particularly advantageous in sectors like oil and gas, where operational integrity is critical. Furthermore, maintenance needs should be assessed; electric ball valves often require less frequent servicing than manual valves, leading to enhanced overall system performance and reduced labor costs over time.