In the contemporary landscape of fluid control systems, the significance of selecting appropriate valves cannot be overstated. Among the various types of valves available, the PVC gate valve stands out as a remarkable choice due to its unique attributes and advantages. PVC gate valves are specifically designed to facilitate the efficient regulation of fluid flow, making them integral components in a wide array of applications, from residential plumbing to large industrial setups. Their lightweight nature, resistance to corrosion, and affordability make PVC gate valves not only practical but also economical compared to traditional materials. Furthermore, the ease of installation and maintenance associated with these valves enhances their overall appeal. This exploration will delve into the numerous benefits of employing PVC gate valves, shedding light on why they are an increasingly preferred option for those seeking reliability and efficiency in fluid control solutions.

In the contemporary landscape of fluid control systems, the significance of selecting appropriate valves cannot be overstated. Among the various types of valves available, the PVC gate valve stands out as a remarkable choice due to its unique attributes and advantages. PVC gate valves are specifically designed to facilitate the efficient regulation of fluid flow, making them integral components in a wide array of applications, from residential plumbing to large industrial setups. Their lightweight nature, resistance to corrosion, and affordability make PVC gate valves not only practical but also economical compared to traditional materials. Furthermore, the ease of installation and maintenance associated with these valves enhances their overall appeal. This exploration will delve into the numerous benefits of employing PVC gate valves, shedding light on why they are an increasingly preferred option for those seeking reliability and efficiency in fluid control solutions.

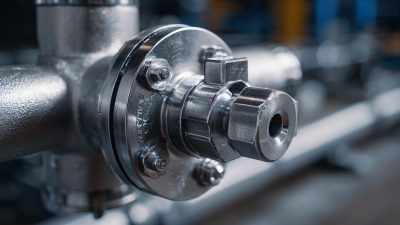

PVC gate valves have gained significant traction in various applications due to their unique features and advantages. These valves are made from polyvinyl chloride, a durable and corrosion-resistant material, making them ideal for fluid control systems in both commercial and residential projects. One of the key benefits of using PVC gate valves is their ability to provide a tight seal, which minimizes leakage and ensures efficient fluid management. According to industry reports, the use of PVC gate valves can reduce maintenance costs by up to 25%, primarily due to their resistance to corrosion and chemical damage.

PVC gate valves have gained significant traction in various applications due to their unique features and advantages. These valves are made from polyvinyl chloride, a durable and corrosion-resistant material, making them ideal for fluid control systems in both commercial and residential projects. One of the key benefits of using PVC gate valves is their ability to provide a tight seal, which minimizes leakage and ensures efficient fluid management. According to industry reports, the use of PVC gate valves can reduce maintenance costs by up to 25%, primarily due to their resistance to corrosion and chemical damage.

Additionally, PVC gate valves are lightweight and easy to install, which can lead to faster project completion times. For instance, in ongoing infrastructure developments such as the Aquero Blvd Extension in Laredo, the implementation of PVC gate valves contributes to streamlined construction processes, enhancing overall project efficiency. Furthermore, the versatility of PVC gate valves allows them to be utilized in various applications, from water supply systems to wastewater management, showcasing their adaptability in addressing fluid control challenges across diverse environments.

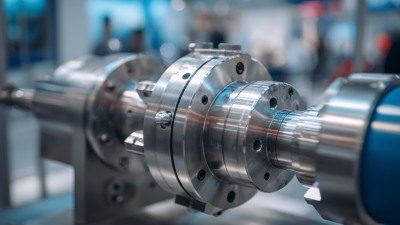

When considering fluid control solutions, a comparative analysis between PVC gate valves and traditional materials such as brass or ductile iron reveals significant advantages. According to a report by the American Society of Plumbing Engineers (ASPE), PVC gate valves offer reduced weight, which simplifies installation and maintenance. Traditional materials can be cumbersome, leading to increased labor costs and installation time. PVC's lightweight nature allows for easier handling, ultimately contributing to enhanced operational efficiency in various settings.

Moreover, the corrosion resistance of PVC provides a notable edge over traditional metals. A study by the National Association of Corrosion Engineers (NACE) indicates that corrosion-related failures result in billions in repair costs annually. PVC gate valves, being inherently resistant to many chemicals, significantly reduce the risk of leakage and failures, thereby enhancing system reliability. This longevity translates to lower lifecycle costs, making PVC a more economical option in fluid control applications.

Tips: When selecting gate valves, always consider the specific fluid compatibility with the valve material. Pay attention to pressure ratings and temperature limits to ensure optimal performance. Regular inspections can help identify potential issues early, prolonging the life of your fluid control systems.

When it comes to efficient fluid control, several factors influence the performance of PVC gate valves. One of the most critical aspects is the design and construction of the valve itself. According to a report by the American Society of Plumbing Engineers, valves with a smooth internal surface significantly reduce turbulence, leading to lower pressure drops and energy consumption during operation. This is particularly important in large-scale industrial applications, where even minor inefficiencies can result in substantial operational costs over time.

Another influential factor is the size and compatibility of the valve within the system. An optimal valve size ensures adequate flow rates and minimizes energy loss. The Hydraulic Institute reports that properly sized PVC valves can contribute to energy savings of up to 25% compared to oversized counterparts. Moreover, the chemical resistance of PVC can enhance longevity and reliability in fluid control systems, reducing the need for replacements and maintenance, which further supports efficiency. Understanding these factors empowers industries to select the right PVC gate valves, ultimately optimizing fluid control processes.

PVC gate valves have emerged as a popular choice in fluid control systems due to their outstanding maintenance characteristics and extended operational lifespan. Unlike metal valves, which may corrode or rust over time, PVC valves are resistant to chemical degradation and environmental factors. This inherent durability means that they require less frequent replacements, thus reducing overall maintenance costs and downtime. The lightweight nature of PVC also allows for easier handling and installation, making maintenance tasks less cumbersome for operators.

Moreover, regular maintenance practices are simplified with PVC gate valves. Their straightforward design facilitates quick inspection and servicing, enabling users to address issues before they escalate into more significant problems. Routine checks can help identify leaks or blockages early on, ensuring that the system operates efficiently. Additionally, the non-toxic nature of PVC prevents contamination of the fluid being transported, contributing to the integrity of the system over time. Thus, the employment of PVC gate valves not only enhances operational efficiency but also promotes a longer lifespan for the entire fluid control system.

| Feature | PVC Valve | Metal Valve | Longevity (Years) |

|---|---|---|---|

| Corrosion Resistance | Excellent | Poor | 10-20 |

| Weight | Lightweight | Heavy | N/A |

| Maintenance | Low | High | 5-15 |

| Cost | Economical | Expensive | N/A |

| Temperature Range | -40°C to 60°C | -50°C to 150°C | N/A |

PVC gate valves have become increasingly popular in various industries due to their durability, corrosion resistance, and cost-effectiveness. In the agricultural sector, these valves are commonly used in irrigation systems, allowing for precise control of water flow while minimizing leakage.

Their lightweight design makes installation and maintenance simple, facilitating efficient water management essential for crop health and yield.

PVC gate valves have become increasingly popular in various industries due to their durability, corrosion resistance, and cost-effectiveness. In the agricultural sector, these valves are commonly used in irrigation systems, allowing for precise control of water flow while minimizing leakage.

Their lightweight design makes installation and maintenance simple, facilitating efficient water management essential for crop health and yield.

In the realm of chemical processing, PVC gate valves excel in managing fluid flows containing corrosive substances. They provide reliable isolation in piping systems, ensuring safety and preventing contamination.

Additionally, in wastewater treatment facilities, PVC gate valves play a crucial role in controlling the flow of effluent and in the functionality of pumping stations.

Their ability to withstand harsh chemical environments while maintaining integrity makes them a preferred choice across these demanding applications.

These real-world implementations highlight the versatility and effectiveness of PVC gate valves in enhancing operational efficiency across industries.